troubleshooting Gaps/Holes in the 3D Print walls 3D Printing Stack

3D printing holes is quite common, but it can also be challenging. Check out five simple tips to get more accurate holes from your 3D printer. 3D printed holes are almost everywhere. You need them for pins, bolts, bearings, linear rods, and a host of other mechanical components. Without them, assembling certain 3D prints would […]

Accurate 3D printed holes 3Dprinting

Yes, you can 3D print threads using SLA resin 3D printers. It's ideal because it provides high precision and accuracy with your chosen model, but I'd recommend using a resin that can handle screws well. Engineering or tough resins are great for 3D printing screw threads that can be tapped. SLA is a great choice for designing the threads.

3D Printing Holes and Shafts What are the limits.

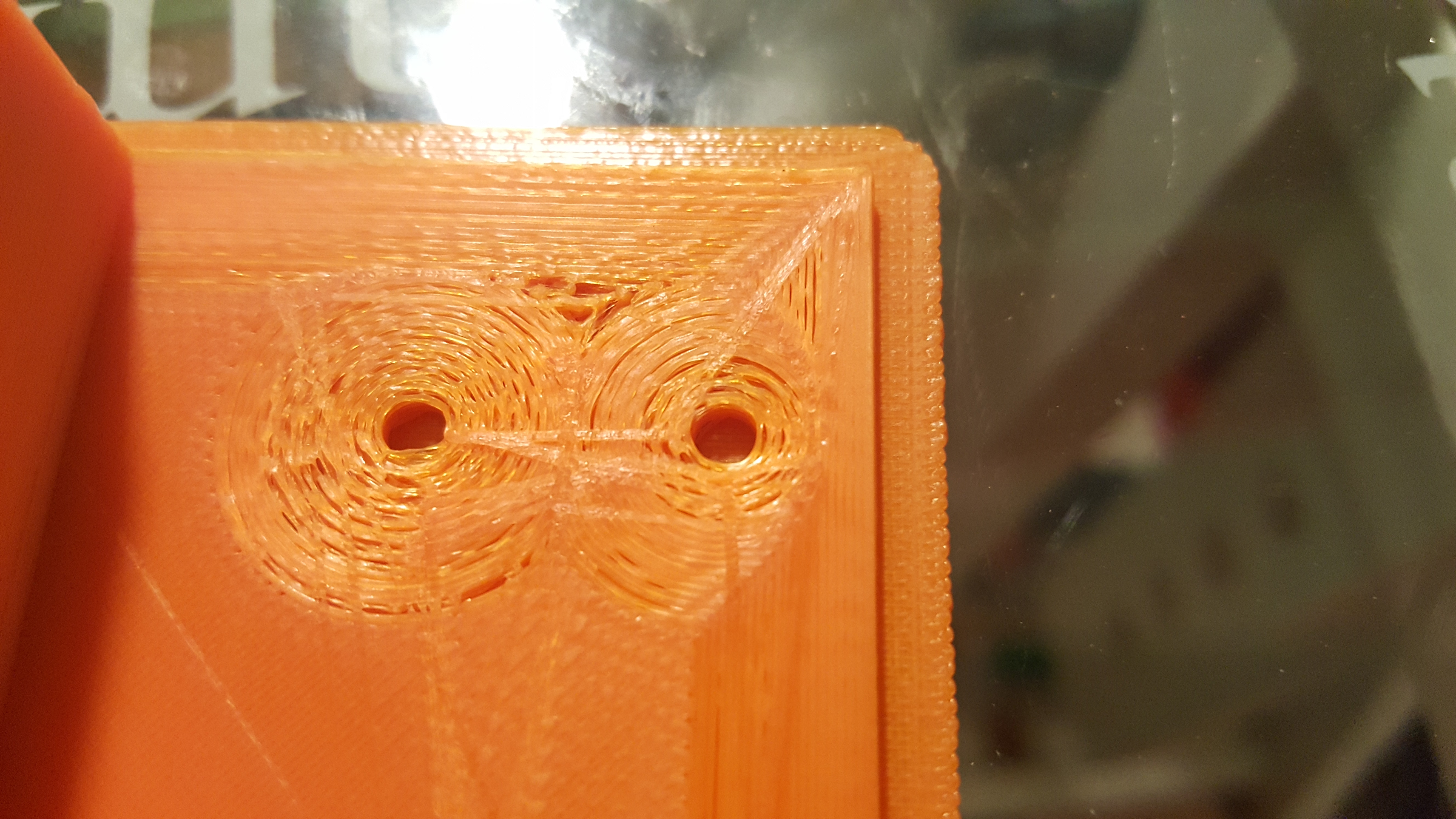

This hexagon and hole design (above) is used to create clamping points on your 3D printed part. It is a method of introducing threaded holes to your design by means of a nut and a bolt! It allows you to securely and reliably join two different parts together (ex. two-part enclosure, or a two-piece mold). Here it is printed twice, once using the.

3D printing Patching vent holes SLA printing YouTube

Creating threaded holes might seem like a straightforward task, but when precision and optimization for mass production come into play, the process becomes more intricate. We will explore various methods of crafting holes for screws and delve into the art of designing them for seamless integration into your 3D-printed parts. Simple Threaded Holes: The most basic approach involves designing a.

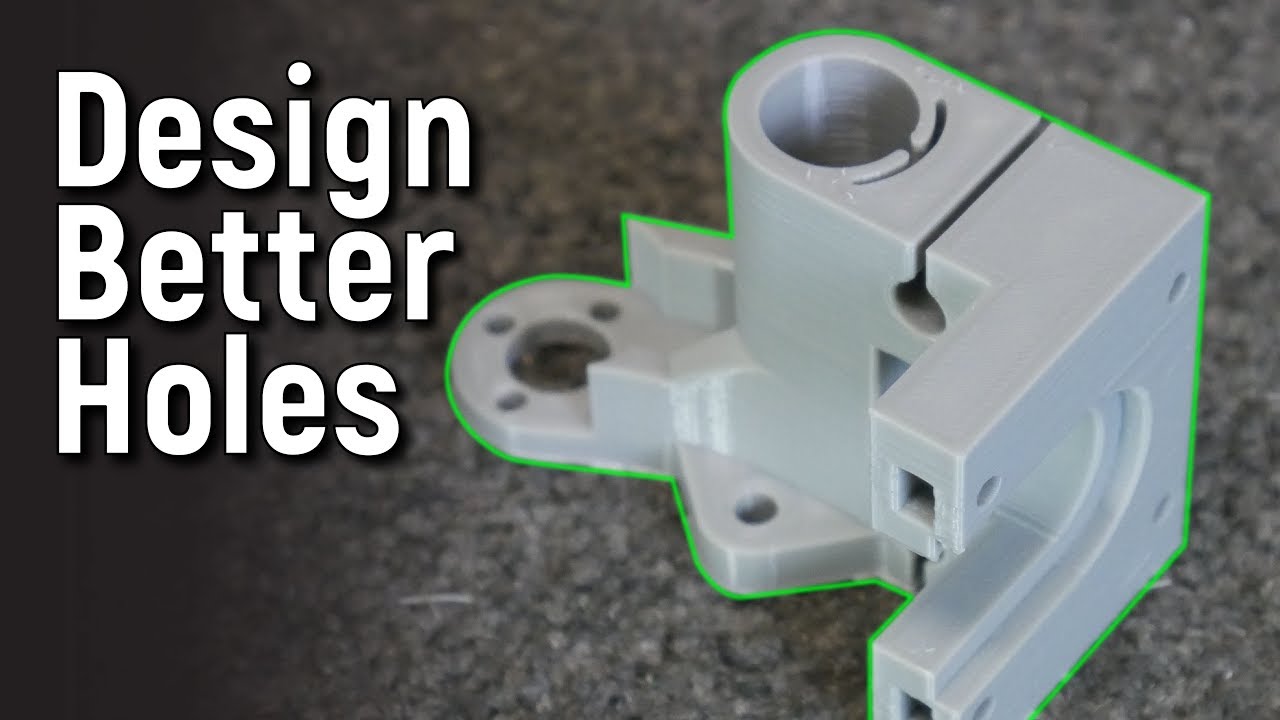

3 Design Tips for Better 3D Printed Holes CAD For Newbies YouTube

Better design. 1. Calibrate Your Extruder. One method of fixing 3D printed holes being too small is to calibrate the extruder. An incorrectly calibrated extruder can result in over-extrusion of the filament, leading to undersized holes. The most important parameter when calibrating your extruder is the E-steps value.

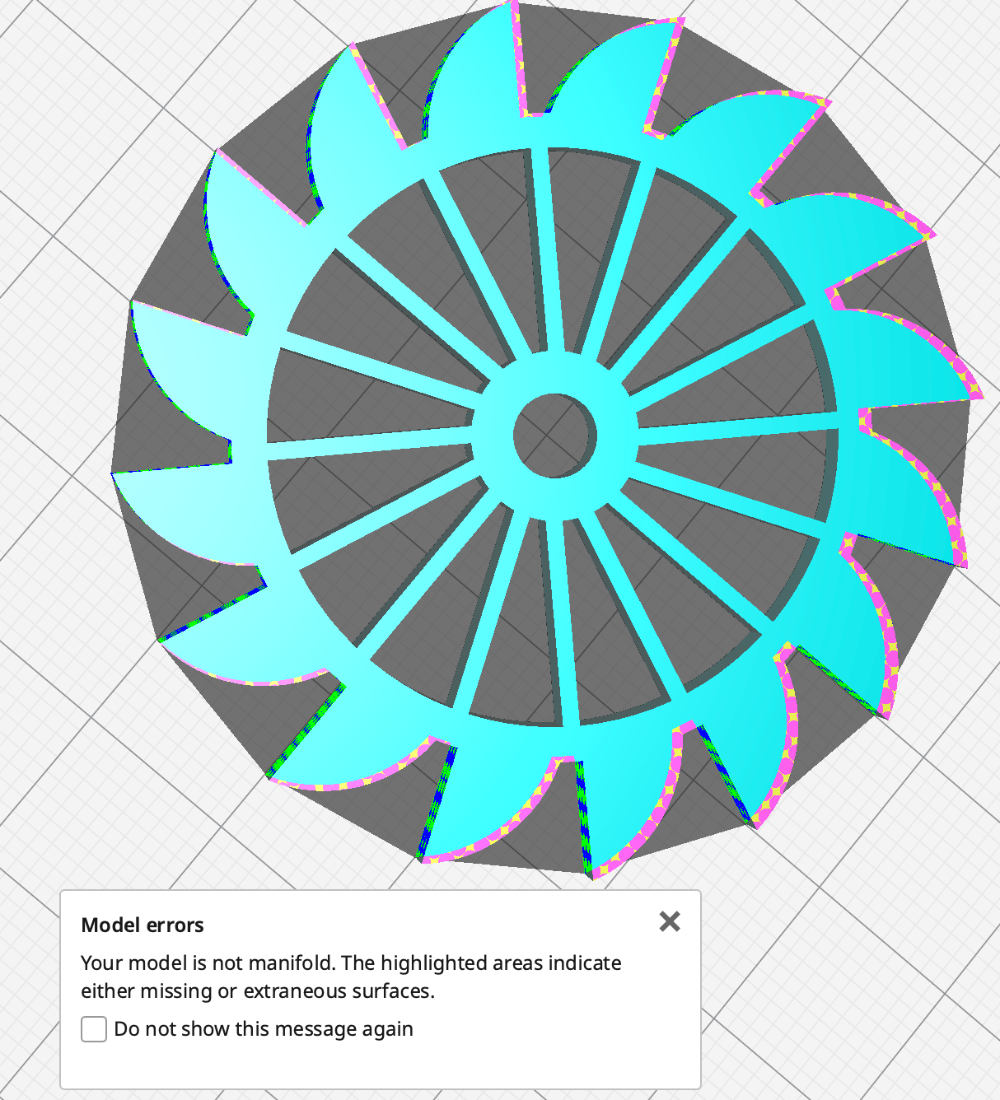

Troubleshooting Guide to 24 Common 3D Printing Problems Part 1 Geeetech

Perhaps the most common cause of the presence of holes, however, is the too small size of the totally solid layer of closure. To be sure to close a model well we should make sure to set at least 6 layers of material and using the thickness 0.2 mm, go to 8 for layers of 0.1 mm and at least 10 for the thickness of 0.05 mm.

Gaps Between Infill and Outline

Post-processing: Some gaps and holes can be fixed after printing by using fillers, sandpaper, vapor polishing, or other methods to smooth out the surface and close up the gaps. Gaps and holes in 3D printing cause major problems: they're ugly to look at, ruin your model, and make useable parts unstable and even brittle.

Creating a hole in 3D file in Meshmixer YouTube

Follow the steps below to fix and prevent the problem. 1. Adjust Top Layer Thickness. One of the main reasons you see gaps in the top layer is a too thin layer. Increasing the thickness can fix the issue as long as the layer has adequate support. All you have to do is increase the number of rows in your top layer, then slice the project again.

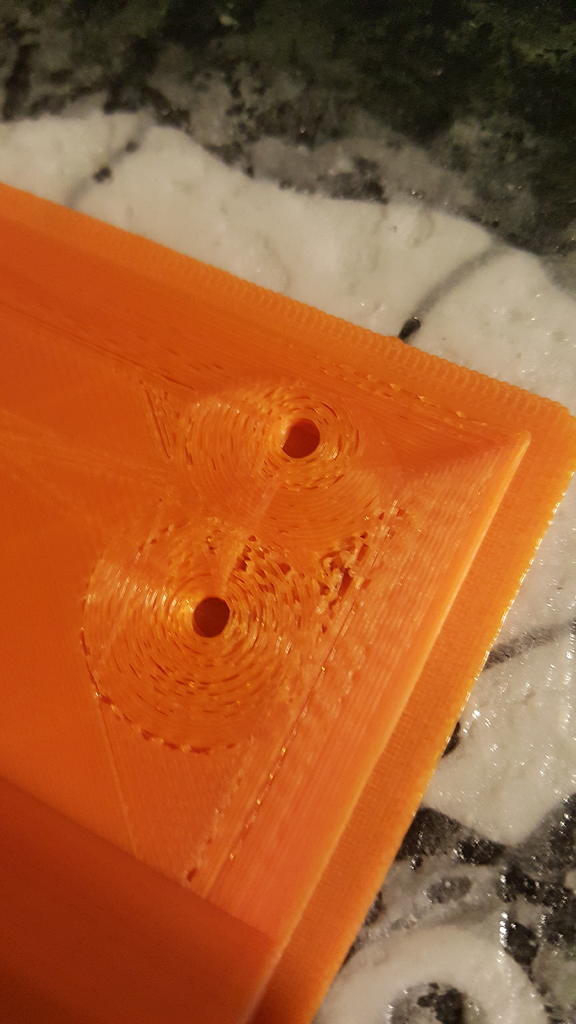

Problem printing any help all prints have these strange holes r

Print perfectly accurate vertical holes with almost no effort, demonstration of polyholes.Results are at the very end of video.Theory: https://hydraraptor.bl.

ball with holes 3D model 3D printable CGTrader

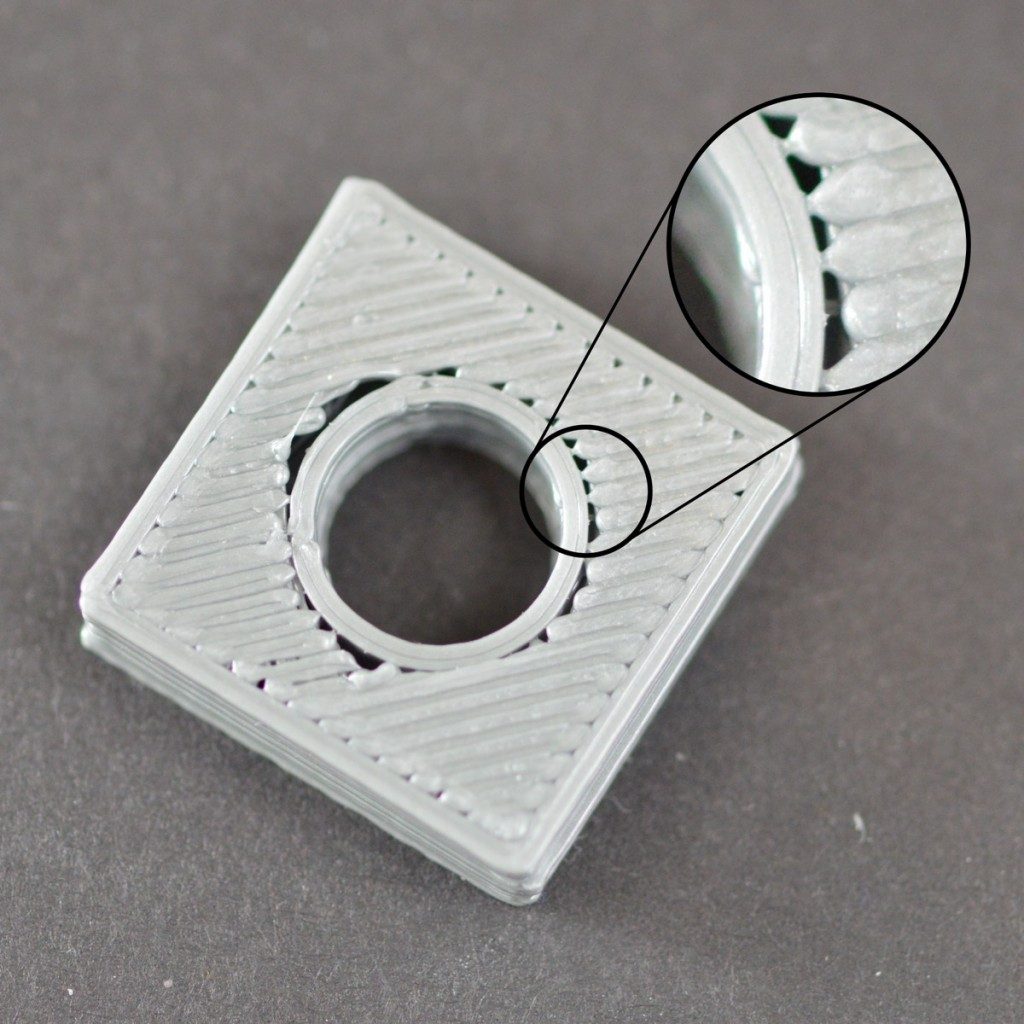

2. Use Differently-Shaped Holes. Another way to 3D print holes that will hold up without supports is to use differently-shaped holes. Sometimes, using holes that aren't typically round-shaped will provide more stability for the overall model. The two most common non-round shapes are chamfered holes and diamond holes.

why the printed holes are smaller than they should be. HydraRaptor

3D Printing isn't a perfect technology, however with clever design we can improve the quality of our parts! Software used - Fusion 360.This video is part of.

troubleshooting Gaps/Holes in the 3D Print walls 3D Printing Stack

When 3D printing holes, you may encounter some common problems such as inaccurate dimensions, poor surface quality, or weak bridging. In this guide, you will learn 5 simple tips to improve your 3D printing holes, such as modifying the bore, using supports, or adjusting the slicer settings. Whether you need holes for screws, pins, or other purposes, these tips will help you achieve better.

Cubify 3D Printing Fans & Fun Matching Holes & Posts Test

Fact-checked. Summary: Under extrusion, fast printing speeds, and low printing temperatures can all lead to holes and gaps in your 3D prints. Optimizing print settings, like first layer settings, extrusion temperature, and ironing, lets you prevent holes and gaps in future prints. Print smoothing or Bondo body filler are good ways to fix gaps.

Printing problem (holes in top layer and warping on the raft) 3D

Gaps in 3D Prints: How to Fix & Avoid Them. by Lucas Carolo. Updated Dec 5, 2023. Gaps in 3D prints are annoying defects that mess up how parts look and work. Check out this guide for easy fixes and how to avoid them!

Not Keeping Printing holes Improve your 3D prints UltiMaker

Achieving a smooth finish in 3D prints is hard when there are gaps and holes. In severe cases, they can even compromise the structural integrity of the print. Fix them with the strategies below.

Printing problem (holes in top layer and warping on the raft) 3D

To 3D print holes without supports, try reducing your layer height, use an optimal printing temperature, so the material above the holes don't sag, use good fan settings with a fan duct to blow cool air on the parts, and design the part with a teardrop shape to create clearance for the top of the hole. The video below by Maker's Muse goes.